Pyro Tempera

Pyro Tempera

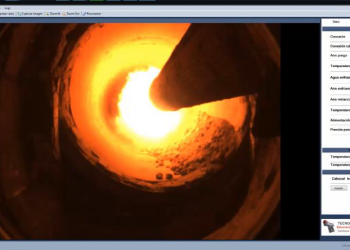

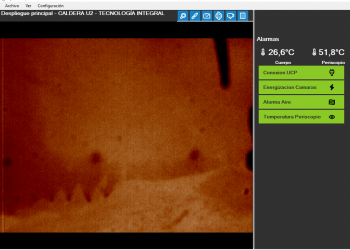

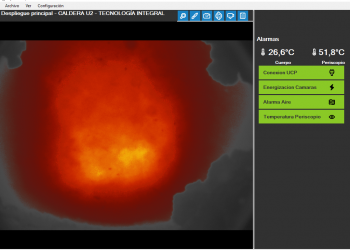

Pyro Tempera® is a system that uses a PyroSpec pyrometric head, which allows the visualization of the kiln calcination zone, the clinker cooling process or the inside of the boiler; and the measurement of internal and material temperatures.

The images of the kiln or boiler interior, obtained by the PyroSpec head, are digitized and processed using the pyrometric imaging technique.

The processing combines the visualization and measurement of temperatures simultaneously and in real time, generating information that is displayed on the furnace/boiler operator’s computer screen, providing tools for optimal operation.

- Live display of the kiln calcination zone, clinker cooling process or boiler interior, depending on the process to be monitored.

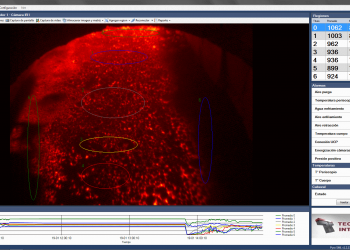

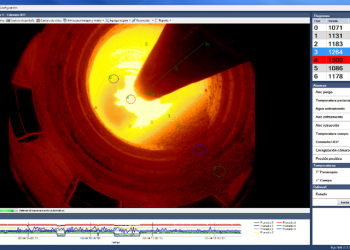

- Configuration of multiple temperature measurement zones of interest for monitoring.

- Automated performance of head protection units when abnormal operating conditions occur.

- Local and remote control of alarm status indications to protect the header from unexpected events such as: low water/air pressure, loss of electrical power, high header temperature, long-term positive pressures.

- Graphical and tabular display of maximum, minimum and average temperature for each of the multiple zones of interest set up.

- Temperature trend graphs displayed in real time with set up time scale.

- Analysis tools for temperature image comparison, differences, longitudinal or cross-sectional profiles, histograms and pseudo-color matrices.